Our customer is a tier-1 automotive equipment supplier, specialized in metal frames manufacturing (machining, stamping, welding). For tier-1 automotive suppliers, the assembly check of the final products before delivery to their customers is a priority. However, when performed by an operator, such quality control tasks come with several drawbacks: these tasks are unrewarding, visually tiring, and highly error-prone.

Furthermore, conventional machine vision solutions are not able to meet the specific needs of our customer:

- Assembly check of different types of components with the same hardware.

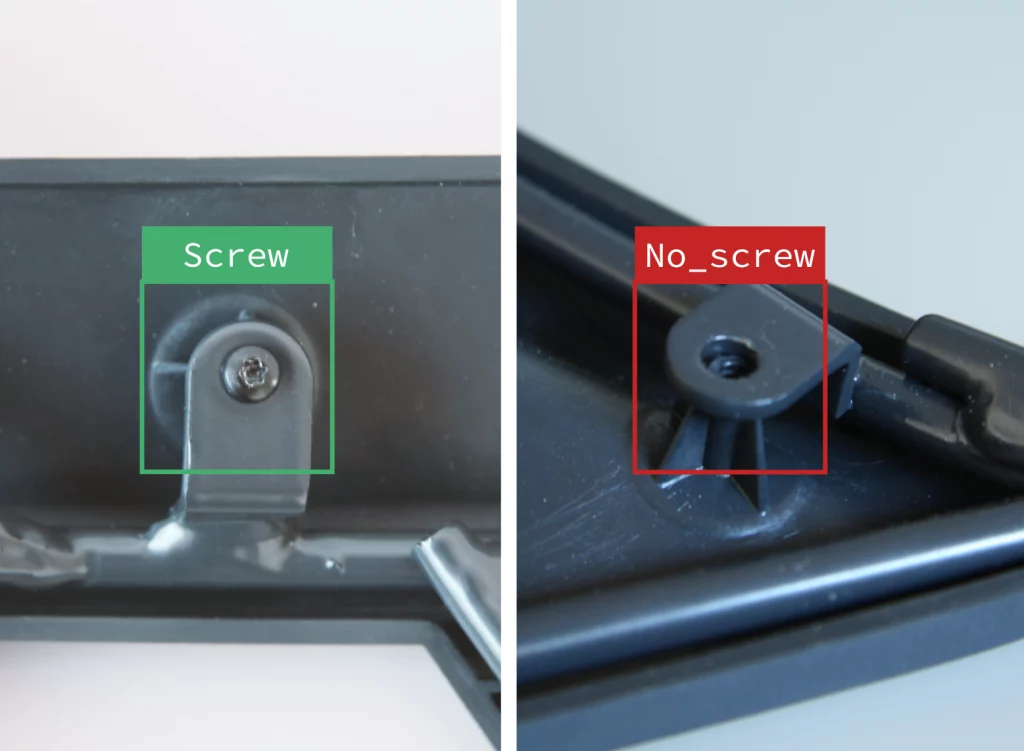

- Assembly check of black screws on a dark background. This is a particularly challenging task because there are no visual features which algorithms can rely on.

ADDI-DATA faced several technical challenges to meet these customer requirements:

A specific Deep Learning model has been trained in order to detect the presence of black

screws, even on dark backgrounds.

ADDI-DATA manufactured a jig to ensure the correct placement of the part before the operator triggers the inspection. The system then generates the printout of a traceability label.

ADDI-DATA designed a solution that meets the different needs, according to the following process:

- The operator places the part on the jig, and then triggers the inspection

- The part reference is automatically detected, then the presence of the different elements is checked in 5 seconds

- At the end of the control, a visual and audible signal is emitted, a traceability label is printed and the results are sent to the Quality Management Software

The complete vision system for automation of metal frame assembly inspection developed by ADDI-DATA consists of:

- Our appliance optimized for computer vision

- A software licence including

- A customized skill developed by ADDI-DATA

- Data reporting to the Quality Management Software

- Connection to an existing industrial printer for the printout of a traceability label

- 1x high-resolution industrial camera

- A jig to ensure the correct placement of the parts to inspect

- A switch to triggers the inspection process

Are you looking for advice?

If you have any questions regarding your future projects, you can always contact team of experts.