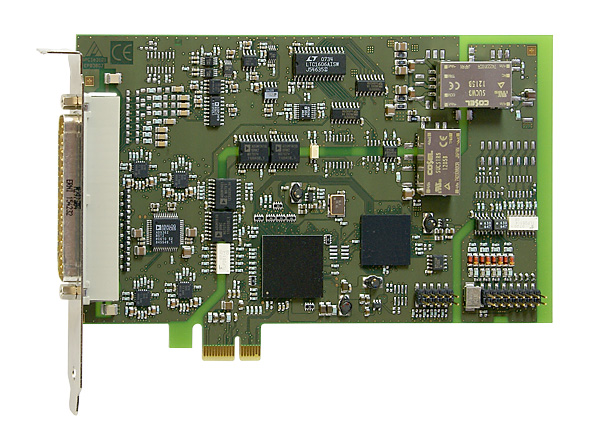

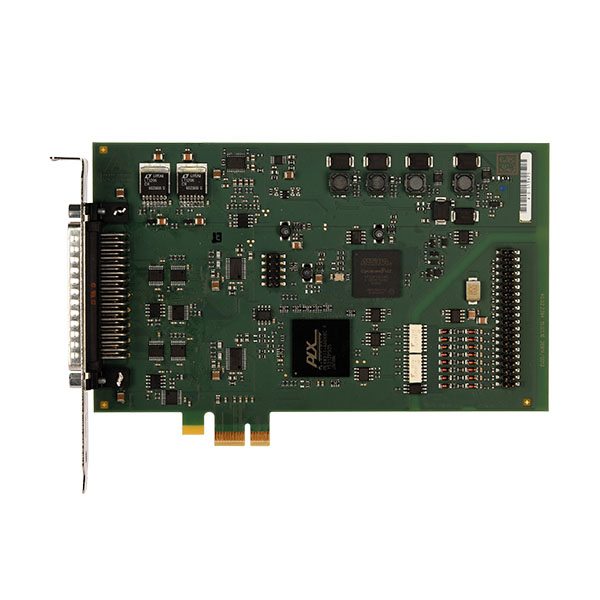

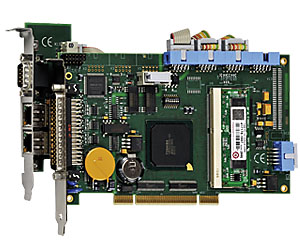

ADDI-DATA develops interference-free DAQ cards for industrial measurement and automation. These DAQ cards are designed to acquire and process a large amount of data quickly and accurately in harsh industrial environments. To guarantee accuracy despite the disturbances to which they are subjected, ADDI-DATA cards have numerous safety devices. Thanks to an adapted connector system, the complete acquisition and control chain (sensor-electronics or electronics-actuator) is immunized.

With the sophisticated and reliable ADDI-DATA DAQ cards, your measurement and automation tasks will be a success!

High quality products, well thought-out design concepts and robust constitution guarantee a reliable function of ADDI-DATA DAQ cards in a harsh industrial environment.

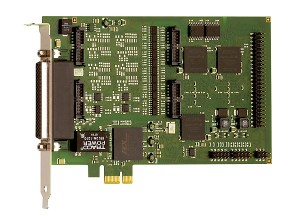

Unique applications due to FPGA technology

A FPGA component has a programmable logic on which you can save your own algorithms in order to adapt the functionality of the DAQ cards to your requirements. This adaptation makes your card unique and improves the performance of your applications.

The onboard algorithms reduce the cycle time of signal acquisition and of regulation tasks. Many ADDI-DATA boards come with a FPGA component. Use the full potential of your card hardware and software resources and thus accelerate your processes.

Bespoke solutions

Benefit from our know-how and our experience and improve the efficiency of your application with our customised solutions. We will be glad to help you – from a small adaptation of a standard product to the complete development of a new product.

Examples

- Adaptation of the signal type, for example 12 V instead of 24 V

- Firmware adaptation

- Drivers for specific operating systems

A well-considered investment

Before investing, make sure that the equipment is well adapted to your requirements. To do so, ADDI-DATA's specialists are ready to come and meet with you in order to select the ideal solution for your measurement or control project.

ADDI-DATA is also committed to making the products you plan to use available to you to use for a test period.

MORE PERFORMANCE WITH ADDI-DATA DAQ cards

- Simplified application design

- Faster processes through FPGA technology

- High-precision measurement results

- Individual customisation

- Safe investments through long-term availability

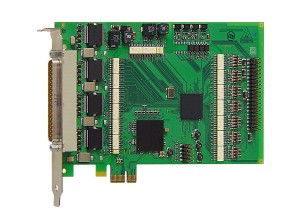

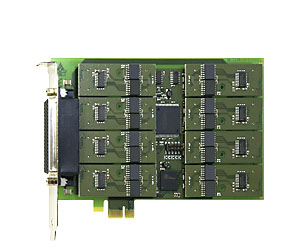

ADDI-DATA offers a wide range of solutions for PCI-Express, PCI, CompactPCI Serial and CompactPCIbus:

- Digital I/O

- Analog I/O or multifunction boards

- Serial interfaces

- Multifunction counter boards

- Motion control boards

For a safe and reliable use in your application, ADDI-DATA DAQ cards are protected by numerous protective circuits like optical isolation, filters, protection against short-circuits etc.

Would you like to test our DAQ cards?

Call us or send us an email to: contact@addi-data.fr

ADDI-DATA DAQ cards are supplied with an extensive software package for a fast and convenient integration into your application: the clever driver concept ADDIPACK,

a wide range of drivers and samples and a configuration tool assist you from the beginning.

ADDIPACK: Easy board handling

- now available as 64-bit version!

For an easy administration of the boards installed in the PC ADDI-DATA has developed a convenient driver system that lists the functionalities of all boards inside your PC on a virtual board. This means that you do not administrate DAQ cards but functionalities, in principle like a resource.

Thus you can easily exchange or add new boards. Changes in the functionalities due to exchanges are immediately visible. An installation of new drivers, for example in case of replacement of PCI cards by PCI-Express boards, is not necessary

The ADDIPACK concept

The ADDIPACK software is organised in two parts:

ADDIDRIVER (ADDIDATA.DLL): The library contains all API functions for the control of ADDI-DATA boards.

Virtual Board Manager: With this program, you can administrate the functionalities of the virtual board. The program helps you by showing a clear visualisation of the virtual board. These two parts are the interface between ADDI-DATA boards and your application.

Supported functionalities

- Digital inputs and outputs

- Analog inputs and outputs

- Temperature measurement

- Pressure measurement

- Resistance measurement

- Inductive sensors

- Timer/ watchdog/ counter

Numerous drivers and samples

Drivers for real-time applications

Linux drivers

Practical simulation

Fast integration in LabVIEW

Individual driver adaptations

FAQ

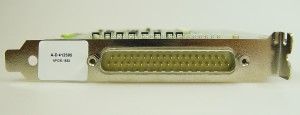

Where can I find the serial number on ADDI-DATA products?The serial number appears in the following form:

The serial number of the cards can be read in two places:

On the card's bracket (visible on the outside of the PC)

On the copper itself (need to open the PC)

Can the FPGA function modules of the counter cards be reprogrammed?Yes, it is possible.

APCI-1710 or CPCI-1710

With the integrated SET1710 program, functions can be assigned or exchanged by drag % drop.

APCIe-1711 or CPCIs-1711

For these boards the SET1711 program is integrated in the Configtools tool. A menu item is dedicated to the choice of the module functions.

What are the available acquisition modes ?

Four acquisition modes are available for the analog inputs. Here is an overview of the parameters available for data acquisition.

A. Simple mode

The software initializes and starts the A/D conversion and reads the digital value of one or more channels after the A/D conversion.

B. Sequence mode

With the DMA (Direct Memory Access) function for direct exchange of two modes with the PC memory, two sequence modes are available:

1. Simple sequence mode

In this example, the interruption is triggered at the end of each sequence (respectively after 5 acquisitions). The acquisition is stopped after three sequences.

2. Sequence mode with delay

The delay between the end of a sequence and the beginning of the next sequence is 20 µs in this example.

C. Auto-Refresh mode

The analog acquisition is initialized and the channel values are recorded on a fixed location on an analog card. The PC reads the data synchronously with the acquisition.

D. Scan mode

1. Simple software scan

The interrupt routine is called by the user after the last interrupt.

2. Simple hardware scan

This mode can be triggered by a rising or falling edge. The hardware triggering allows to start the acquisition independently of the software or for several cards simultaneously.

3. Software continuous scan

4. Software continuous scan with timer delay

5. Hardware content scan

6. Continuous scan with hardware timer delay

What is the difference between a Single-Ended and a Differential Input?

Single-Ended Input - Inputs with one channel connected to system ground

When acquiring analog signals in single-ended mode, spurious signals are recorded with the signal. For this reason, it is recommended to use this mode of operation only on relatively high voltage levels and on short lengths.

Differential input - Two-way input

Interference signals acting on both channels are not taken into account in the measurement since the difference between the two channels is operated at the input. This mode is ideal for lines subject to interference and long lines.