MSX-AI-5000 – Industrial AI appliance for machine vision on the edge

The MSX-AIRIS software is an autonomous computer vision software that does not require a connection to the cloud. It enables the execution of artificial intelligence algorithms in real time, making the system more resistant to disturbances and less sensitive to environmental variations. It contains an intelligent industrial agent software with its user interfaces and allows developers to customize the algorithms executed using development tools (IDE + SDK) in applications named “Skills”.

Description

The MSX-AI-5000 is an artificial intelligence-based industrial edge vision system. Through this product, we offer a solution for industrial quality control and maintenance engineers seeking to automate quality control tasks for manufactured parts, by providing them with our user-friendly complete machine vision system: hardware module, industrial cameras, and AI-assisted embedded processing.

Unlike complex and too specific competing solutions, the MSX-AI-5000 by ADDI-DATA is a versatile product that allows to increase speed and accuracy of error prone tasks such as visual inspection, thus preventing non-detection of defects while ensuring process transparency. This system allows to perform different applications on the same hardware base by installing various skills (see catalog). These skills are developed to best fit specific use cases constraints, and are easily reconfigurable if further requirement arise. The user friendly interface enables an uncomplex administration and setting of the system, thus ensuring maximum efficiency and minimum efforts.

MSX-AIRIS on the edge:

- Multi-camera and camera agnostic

- Data acquisition and management features

- ONNX Deep Learning models deployment (segmentation, classification, object detection …)

- Classic computer vision post-processing: OCR, tracking, object recognition, color filtering, thresholding …

- 2D/3D Machine vision

- Integrable in your MLOps pipelines

- Embedded user interfaces (Web app and Android app)

- OPC UA and MQTT ready

- Customizable with Python SDK and development tools

- Authenticated and encrypted data communication: TLS protocol

Embedded operator-friendly user interface:

- No-coding skill management and system administration

- Easy-to-use camera setup interface

Hardware:

- Based on Nvidia Jetson Xavier NX (other on resquest)

- 1x Gb Ethernet for LAN connectivity

- 4x USB 3.2 ports for UVC cameras

- 2x PoE ports for GigE cameras

- 1x HDMI output for dashboard

- Wi-Fi connectivity

- Cascade mounting with ADDI-DATA products to build an ecosystem

- Other interfaces on request*: 4G, Ethercat…

Fields:

- Quality control

- Predictive and corrective maintenance

- Smart city and many others…

Use cases:

- Manufactured parts visual inspection

- Assembly check

- Surface inspection

- 3D volumetric measurement and many others…

Service on request:

Deep learning-embedded neural network training and dataset creation for customer-specific industrial needs.

Contact us to request an offer!

Cubic 3D measurement:

- No calibration

- Millimetric precision

- Multi-object

- Low light compatible

- Non intrusive measurement

- High rate measurement

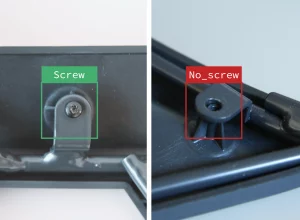

Advanced quality control:

- Feature detection

- Feature classification

- Surface inspection

- Component placement check

- Real-time edge computing

- Multi-object

- Multi-camera

DOWNLOADS

Datasheets

English version French version German version

User guide

English version French versionAPPLICATIONS

Dimensional measure of orthopedic knit fabrics

Dimensional measure of orthopedic knit fabrics

Our customer is one of the French market leaders in the field of orthopedic textiles. The control of the industrial knit fabrics is essential to ensure the quality of the final product.

Assembly components check on black metal frames

Assembly components check on black metal frames

Our customer is a tier-1 automotive equipment supplier, specialized in metal frames manufacturing (machining, stamping, welding). For tier-1 automotive suppliers, the assembly check of the final products before delivery to their customers is a priority.