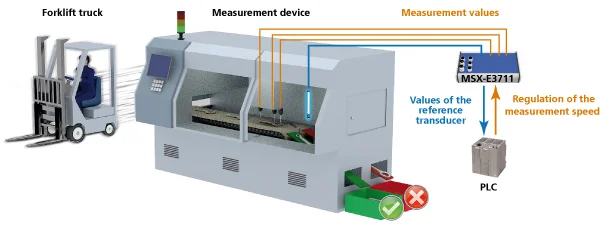

In a measurement device, inductive displacement transducers are acquired simultaneously and the measurement values are processed with a PLC. From time to time, the measurement values show extreme fluctuations which causes a rise in rejects.

The manual re-measurement of the rejects establishes that most of the rejects were not actually rejects. An exact analysis brought forward the reason: forklift truck traffic passing close to the machine created vibrations that caused pseudo rejects.

The intelligent Ethernet length measurement system MSX-E3711 acquires the inductive displacement transducers simultaneously. Parameterisation is effected through ModBus TCP. The measured values then are transferred via Ethernet to the PLC that controls the machine. As a reference, an additional transducer is acquired.

As soon as a forklift truck approaches, it begins to vibrate. Also on the other transducers the measurement values begin to fluctuate which would result inevitably in inaccurate measurement values. In order to keep the measurement accuracy of the transducers despite of the vibration, the PLC reduces the acquisition speed of the MSX-E3711: The integrated average determination is activated through Modbus command. This reduces the acquisition speed but ensures the precision of the measurement values.

In critical cases, the acquisition can even be stopped.

As soon as the forklift truck has passed the machine and the vibration is over, the PLC resets the acquisition parameters through ModBus command. Then, the measurement is effected with maximum speed again.Thus the rejects due to measurement errors are considerably reduced and the quality and reliability of the measurement values is significantly increased.

Are you looking for advice?

If you have any questions regarding your future projects, you can always contact team of experts.