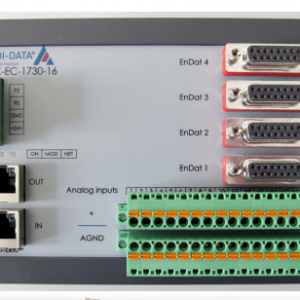

MSX-E1731 – Fieldbus DAQ System – Counting Inputs

The Ethernet EnDat counter system MSX-E1731 has 4 EnDat 2.2 inputs with status LEDs, 16 digital I/O, 24 V, and a 24 V trigger input. The system was especially developed for the acquisition of sensor- and actuator data close to the sensor in the harsh industrial environment and has a robust normed metal housing with the degree of protection IP 65. It has an extended temperature range from -40°C to +85°C. The ARM®9 32-bit processor allows the calculation of the acquired values. The Development Mode allows to customise applications individually. Through synchro connection, several MSX-E systems can be cascaed and synchronised with one another in the µs range.

Description

Features

- 24 V digital trigger input

- ARM®9 32-bit processor

- 64 MB onboard SDRAM for storing data

- Robust standardized metal housing

- Power Save Mode: Reduced power consumption when no acquisition runs

Sensor inputs

- 8-pin M12 female connectors

- 4 x EnDat counter inputs for the acquisition of EnDat encoders

- Max. clock frequency 4.5 MHz

- Voltage supply of the EnDat encoders via M12 female connectors: 5 V ±10%

- Output of the values as raw value or position value (mm or degree°)

- Communication LED for each EnDat input

Safety features

- Status LEDs for fast error diagnostics

- Optical isolation 1000 V

- Input filters

Interfaces

- Fast 24 V trigger input

- Ethernet switch with 2 ports

- Synchronisation/trigger In/Out

- Line in for 24 V supply and cascading

Communication interfaces

- Web server (configuration and monitoring)

- Command server SOAP for transferring commands

- Data server (TCP/IP or UDP socket) for sending acquisition data

- Event server (TCP/IP socket) for sending system events (Diagnostics such as temperature, short-circuits …)

- Command server Modbus TCP and Modbus (UDP) for sending commands

Synchronisation/time stamp

Time stamp

Several MSX-E systems can be synchronised with one another in the µs range through a synchro connection. This allows to start a synchronous data acquisition, to generate trigger events and to synchronise the time on several MSX-E systems. Furthermore, the systems have a time stamp that logs the point in time at which the data was acquired by the system.

The combination of synchronisation and time stamp (TS) allows the clear allocation of signals that were captured by several systems.

EnDat

EnDat is a bidirectional synchronous-serial interface for position measurement devices. This interface allows to read out absolute position values and parameters, to write status and initialisation registers and to transfer additional information about the position value. In addition, ADDI-DATA EnDat 2.2 solutions support the evaluation of diagnostic values and access to the OEM memory. Data is transferred serially.

- Fast data transfer

- Signal delay time compensation

- High contour accuracy

- High transmission safety

- No need for additional sensors: Evaluation (temperature, limit switch, etc.)

- Serial transmission: only 4 lines necessary (EnDat 2.2)

- Single-line wiring (M12, 8-pin)

- Automatic parameterisation through electronic type plate

Acquisition modes

Asynchronous acquisition

With the asynchronous acquisition, the digital inputs can be read out via SOAP or Modbus function. For each function call, the values of one channel are transmitted.

Synchronous acquisition

With the synchronous acquisition, the inputs are first initialised and then the acquisition is parameterised. The acquisition runs automatically depending from a trigger source. Either the 24V trigger input or a synchro trigger can be used as trigger source

Onboard programming / stand-alone operation

Development mode

With the Development mode of the MSX-E systems you can customise your measurement, control and regulation applications to fit your requirements. The programs run directly on the MSX-E systems, which has two advantages: external PCs are relieved and you can process data freely according to your requirements. This helps you to improve the efficiency of your processes and to secure your investments.

ConfigTools

The ConfigTools program allows an easy administration of the MSX-E systems. These are automatically detected in the network. ConfigTools

consists of common and specific functions. In addition, with ConfigTools, the complete configuration of a MSX-E system can be saved and transferred to another system of the same type (clone function). ConfigTools is included in the delivery

ConfigTools functions for MSX-E3011:

- Change of IP address

- Display of web interface

- Firmware update

- Save/load system configuration

- Save/load channel configuration

- Monitor for analog inputs

ACCESSORIES

Accessories for Fieldbus DAQ System

Find all the necessary and compatible accessories:

AccessoriesDOWNLOADS

Samples and documentation

For Windows Common functions ConfigTools

Datasheets

English version French version German version

Manuals

English version German versionAPPLICATIONS

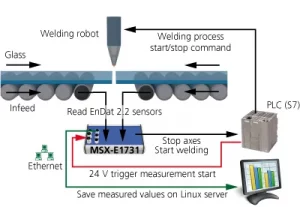

Position acquisition in a welding process

Position acquisition in a welding process

Learn how Ethernet counter systems can help you acquire positions and ensure a high quality welding process.