Our customer is one of the French market leaders in the field of orthopedic textiles. The control of the industrial knit fabrics is essential to ensure the quality of the final product. However, when performed by an operator, such quality control tasks suffer from several drawbacks:

- These tasks are unrewarding and generate a lot of eyestrain

- The reproducibility of the measure is complex to ensure

- It generally constitutes a bottleneck that slows down the production rate (20 to 30 seconds per knit fabric)

ADDI-DATA faced several technical challenges to to meet these customer requirements, especially to ensure the reproducibility of the process regardless the position, the orientation and the folds of the knit fabric. To speed up the quality control process, the solution needs to be integrated into the running process and carry out the measurement of a knit fabric in a few seconds.

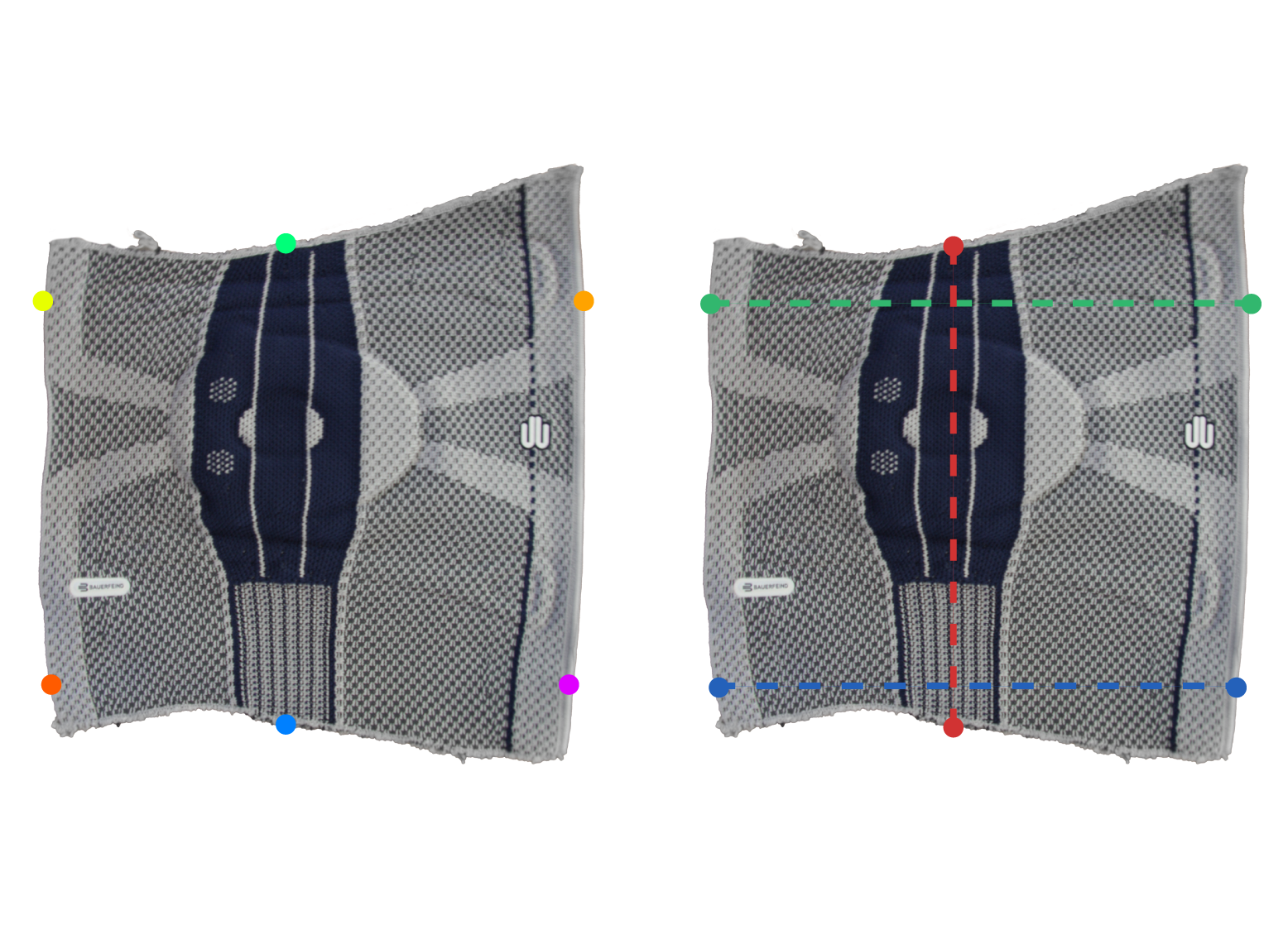

A neural network has been trained to automatically determine the measurement points for each knit fabric reference.

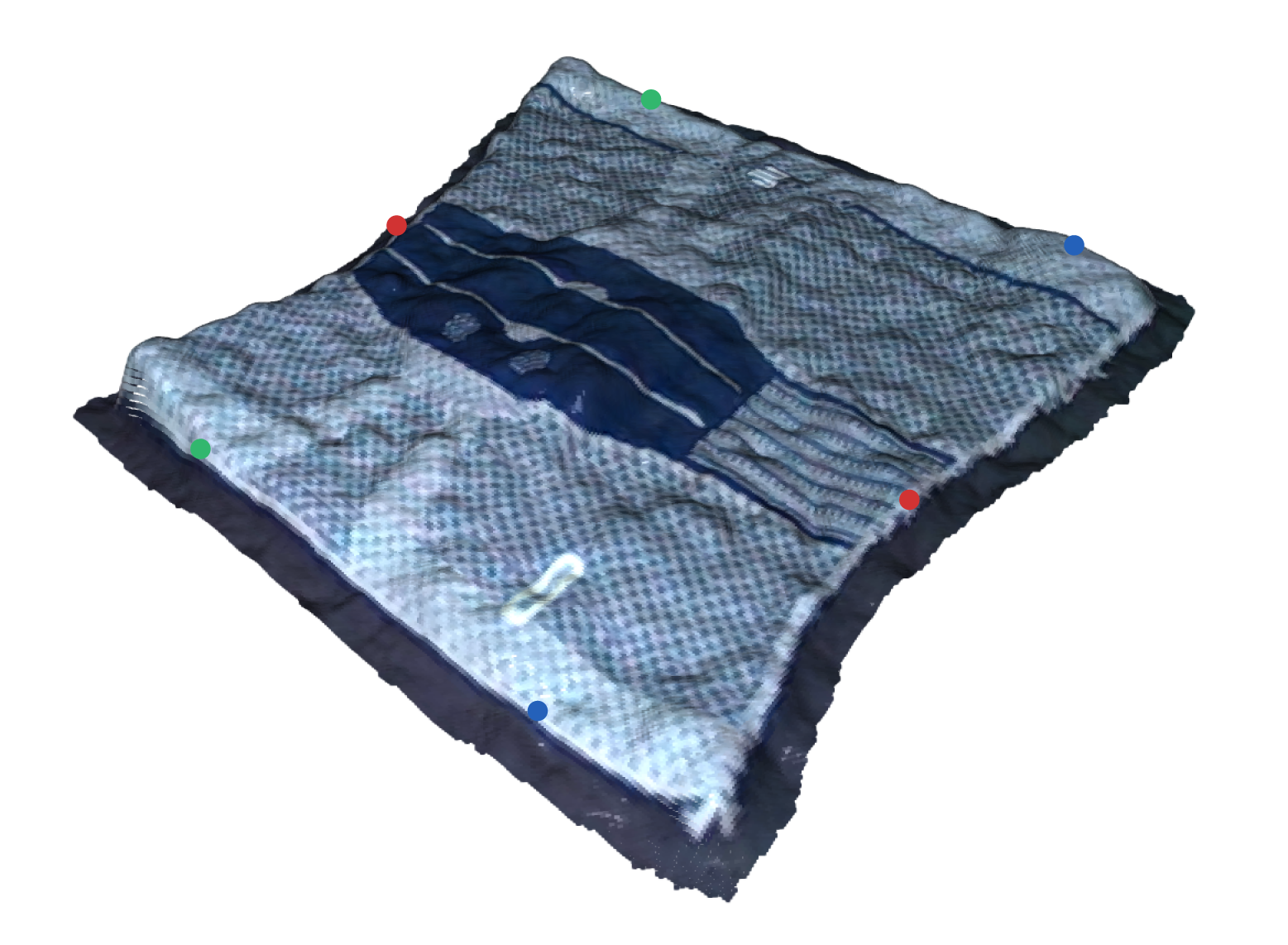

ADDI-DATA has developed a method for geodetic distance measurement along the knit fabric surface. This method is based on the use of multiple 3D cameras, to avoid missing data in the points cloud.

ADDI-DATA designed a solution that meets the different needs, according to the following process:

- The operator clips all the knit fabrics to be measured on an overhead conveyor, then triggers the control of the whole batch

- Each knit fabric is automatically carried to the inspection area

- The measurement process of one knit fabric takes up to 5 seconds

- After the dimensional control, the knit fabrics are stored in the corresponding unloading areas (OK or NOK)

- At the end of the batch inspection, a visual and audible signal is emitted, and the results are reported on the dashboard and sent to the Quality Management System

The complete machine vision system for the automation of dimensional measurements of knit fabrics designed by ADDI-DATA consists of:

- Our appliance optimized for computer vision

- A software licence including

- A customized skill developed by ADDI-DATA

- Data reporting to a shopfloor dashboard

- Data reporting to the Quality Management System

- 4x high-resolution 3D cameras

- A dashboard for data reporting

- A conveying system to dispatch OK and NOK knit fabrics

- A switch to control the measuring process of a batch of knit fabrics

Are you looking for advice?

If you have any questions regarding your future projects, you can always contact team of experts.