In order to optimise the press process and to reduce defective parts the press depth of a press shall be monitored cycle-dependently. As an installation close to the press is necessary, the system has to be resistant to shocks and vibrations. Furthermore, the measurement system must be easy to handle and allow a fast change of dies.

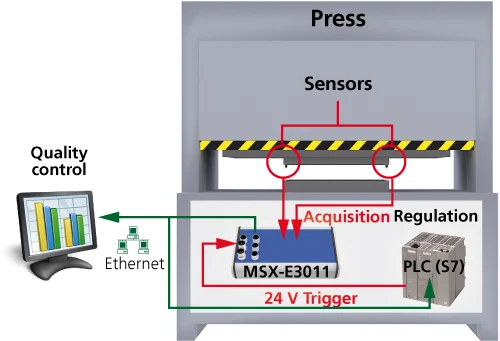

A die (tool) with a sensor for distance measurement is installed inside the press.During the distance measurement process which is started and ended via trigger signal, the press depth is detected. The MSX-E3011 Ethernet-based analog input system acquires the sensor values at a 100 kHz frequency and a 16-bit resolution and transfers them directly to the control unit. Then the control unit compares them with the predefined values and adjusts the settings if necessary. For statistical purposes the acquired data is also transferred to the quality assurance department through the company network.

- Different dies allowed: numerous sensor types can be connected as the system is able to acquire current signals as well as voltage signals

- Robust system for a use close to the press

- Precise measurement results through protective measures to guarantee resistance to perturbations

Are you looking for advice?

If you have any questions regarding your future projects, you can always contact team of experts.